Part Details | TAPERED ROLLER BEARING

3110-00-151-9553 A cylindrical device in which the inner cone or outer cup turns upon a single or double row of tapered hardened rollers which roll easily in a race, thus minimizing friction and designed to carry a radial load and capable of sustaining axial thrust. Excludes BEARING, ROLLER, THRUST.

Alternate Parts: 926261, 926261, 28303, 2803, 2803, 4920A, 3372, X3372, 4920A, 3372, X3372, MS1908910, MS19089-10, NA4414344363D, NA44143-44363D, NA4414344363D, NA44143-44363D, NA4414344363D, NA44143-44363D, 91117805, 3110-00-151-9553, 00-151-9553, 3110001519553, 001519553

| Supply Group (FSG) | NSN Assigned | NIIN | Item Name Code (INC) |

|---|---|---|---|

| 31 | JAN 01, 1961 | 00-151-9553 | 00021 ( BEARING, ROLLER, TAPERED ) |

REFERENCE DRAWINGS & PICTURES

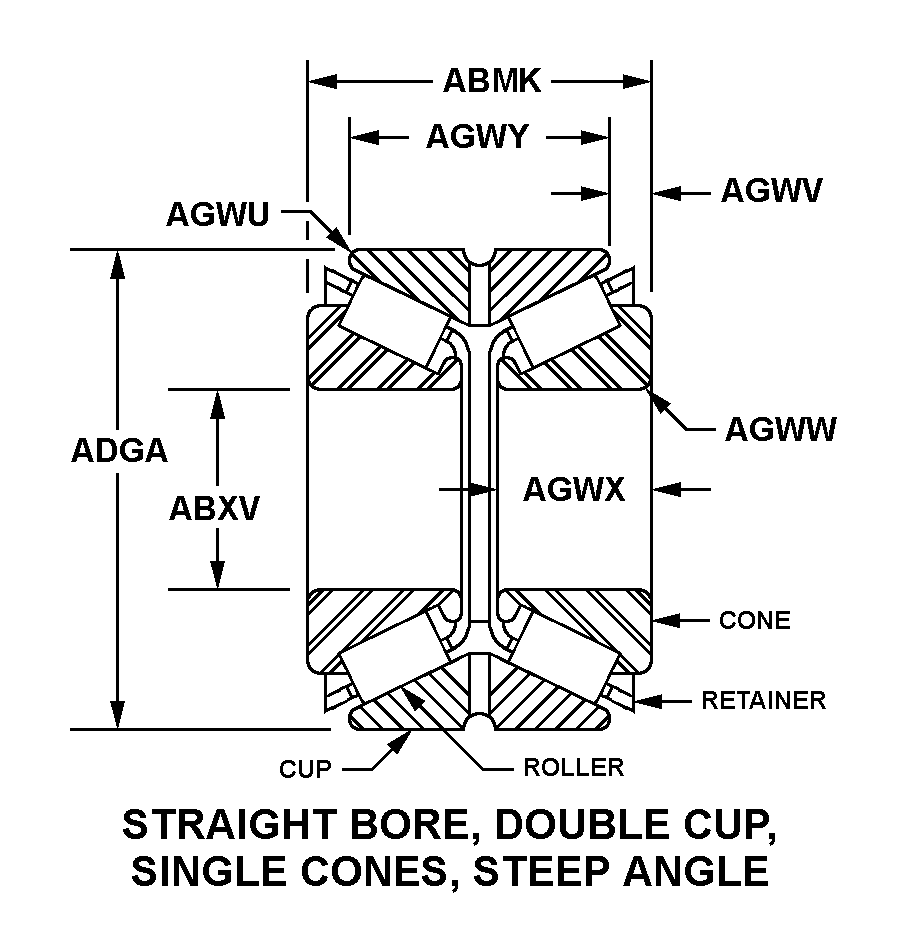

STRAIGHT BORE, DOUBLE CUP, SINGLE CONES, STEEP ANGLE

Cross Reference | NSN 3110-00-151-9553

| Part Number | Cage Code | Manufacturer |

|---|---|---|

| 926261 | 86403 | CHRYSLER CORPSERVICE AND PARTS OPNS |

| 926261 | 12204 | DAIMLER CHRYSLER |

| 28303 | 30076 | HYSTER-YALE GROUP, INC. |

| 2803 | 30076 | HYSTER-YALE GROUP, INC. |

| 2803 | 04627 | HYSTER-YALE GROUP, INC. |

| 4920A | 79410 | LIBERTY VENTURES INTI LLC |

| 3372 | 79410 | LIBERTY VENTURES INTI LLC |

| X3372 | 79410 | LIBERTY VENTURES INTI LLC |

| 4920A | 1L170 | MARYSVILLE MARINE DISTRIBUTORS, INC. |

| 3372 | 1L170 | MARYSVILLE MARINE DISTRIBUTORS, INC. |

| X3372 | 1L170 | MARYSVILLE MARINE DISTRIBUTORS, INC. |

| MS19089-10 | 96906 | MILITARY STANDARDSPROMULGATED BY MILITARY DEPARTMENTS |

| NA44143-44363D | 60038 | TIMKEN CORPORATION, THEDIV TIMKEN COMPANY |

| NA44143-44363D | K0018 | TIMKEN EUROPE A BRANCH OF THETIMKEN COMPANY |

| NA44143-44363D | K0036 | TIMKEN UK LTD |

| 91117805 | U0724 | VAUXHALL AFTERSALESDBA INFO-TBILISI |

Technical Data | NSN 3110-00-151-9553

| Characteristic | Specifications |

|---|---|

| STYLE DESIGNATOR | STRAIGHT BORE, DOUBLE CUP, SINGLE CONES, STEEP ANGLE |

| OVERALL WIDTH | 2.1875 INCHES NOMINAL |

| BORE DIAMETER | 1.4375 INCHES NOMINAL |

| OVERALL OUTSIDE DIAMETER | 3.6250 INCHES NOMINAL |

| BACKFACE CORNER RADIUS | 0.0620 INCHES NOMINAL |

| STANDOUT WIDTH | 0.3125 INCHES NOMINAL |

| CONE CORNER RADIUS | 0.0310 INCHES NOMINAL |

| CUP WIDTH | 1.5625 INCHES NOMINAL |

| STANDARD TOLERANCE DESIGNATION | AFBMA CLASS 4 |

| RETAINER FABRICATION METHOD | PRESSED |

| SPECIAL FEATURES | OPERATING TEMPERATURE NOT TO EXCEED 121 DEG C/250 DEG F; OIL HOLE AND GROOVE IN CUP; 0.0040 IN. MIN,0.0060 IN. MAX BENCH LATERAL |